PROJECT

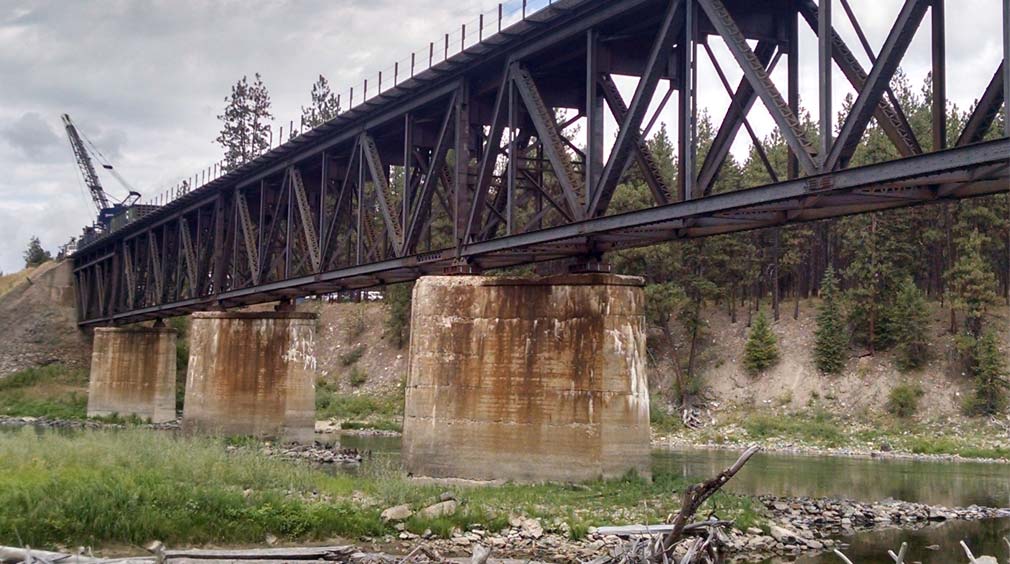

The bridge had an open deck system, meaning the railroad ties are directly connected to the steel truss with no rock ballast. Rock ballast is a vital bridge component as it is used to bear the live load from railroad ties and adds track stability and flexibility, among other safety elements such as facilitating water drainage. Because rock ballast was not present, the floor beams and stringers showed signs of fatigue and cracking. Additionally, the amount of train loads over the years can cause structural steel to become weak, which can lead to cracking.

SOLUTION

MRL hired KLJ to design a strengthening plan, new floor beams and stringers, new bearing and jacking system to ensure the bridge could function safely in the future. KLJ was also asked to analyze the truss with three types of car loads MRL utilized on their system. Truss strengthening was completed in 2015 and the floor beam, stringer, deck, and bearing replacement was completed during the summer of 2016.

RESULTS

The project provided a safer bridge to move goods through the Rocky Mountains with the new closed deck, ballasted system. Since adding a closed deck meant the truss members and gusset plates needed to be strengthened, the added security of knowing those parts are not a weakness concern is a major safety enhancement. It is easier for MRL to maintain, meaning it reduced the amount of opportunities for an accident. The project was completed in two construction seasons and within the client’s schedule. The Montana Rail Link Bridge No. 207 was an American Council of Engineering Companies award winner in Montana. The award recognizes uniqueness and/or innovative applications, future value to the engineering profession and perception by the public, social, economic, and sustainable development considerations, complexity, and successful fulfillment of client/owner's needs.